Industries

The industrial sector uses around 25% of energy in Europe. 46,9% of that is used for process heat, making it one of the biggest influences of the energy transition.

While the sectors households and transport are getting electrified by heat pumps and electric vehicles, the industry is still mostly dependent on fossil fuels. Electric energy only has a share of 4% in process heat production. Roughly 75% comes from natural gas, coal and other fossil fuels.

The Power-to-Heat plant can electrify heat processes of any kind. The most applications are in the industries of food, paper, chemical and wood. Generally speaking all industries that have e.g. drying processes can profit from this technology.

Our recycling plants are used in the battery industry and the metal industry. The Metal Flow Heater's application is also the metal industry.

Paper Industry

A lot of energy and especially heat is needed to produce paper. To produce one ton of corrugated base paper, 1.260 kWh of energy is needed. 950 kWh of that energy is needed as heat.

Especially drainage and drying processes need tons of energy. That is why most large paper factories have their own power plants that produce electricity and steam. To achieve climate neutrality, these fossil fueled power plants will have to be shut down and steam has to be produced in another way.

A Power-to-Heat plant is the optimal substitution. It produces large quantities of heat at low cost.

Food Industry

frying, heating, steaming, evaporating, drying, etc..

Nearly all food products need heat in their production process. A few examples are the production of sugar, the heat treatment of milk, baking bread or spray drying liquids to create powder.

A Power-to-Heat plant can electrify every process whether the heat transfer medium is thermal oil, steam, air or water.

Wood Industry

Especially the wood materials industry is very heat intensive.

Heat is needed to dry the raw material as well as in the hot pressing process of chipboards or fiberboards, where wood and binder are pressed into their final shape.

Wood as a resource is already climate friendly. A Power-to-Heat plant enables you to produce your material without CO2 Emissions and fossil fuels.

Chemical Industry

The chemical industry is one of the biggest energy consumer worldwide, which makes a decarbonization especially crucial.

90% of processes in the chemical industry require temperatures under 1.000°C which makes an electrification suitable and reasonable.

Whether it is the process of cracking or the hydrogen production at 900°C or distillation or polymerization.

A Power-to-Heat plant can electrify all of these processes and contribute to the energy transition in the chemical industry.

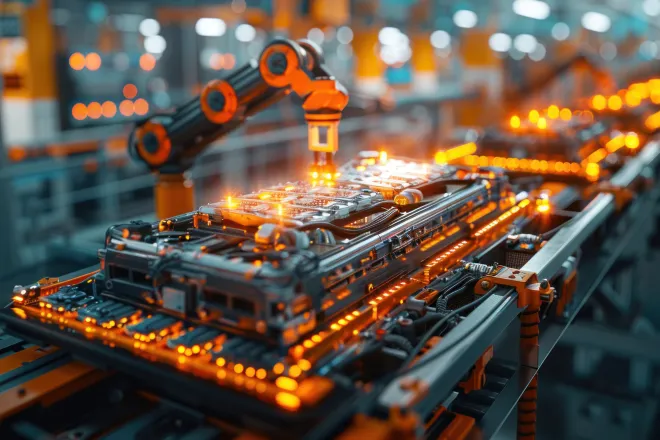

Battery Industry

The demand of Lithium Batteries increases every year. Not only are they used in electric vehicles and portable electronics but also in large energy storages. The amounts of batteries produced is expected to continue to grow which raises the question of the scarcity of resources.

Lithium, Cobalt and Nickel are rare. The development of a efficient circular economy is therefore a priority and makes Europe independent from countries that mine these rare materials.

Our recycling plants take care of the thermal deactivation and the pyrolysis of black mass and enable a safe and efficient recycling process.

Metal Industry

One of the many benefits of metals is their property to be recycled infinitely without quality losses.

Otto Junker supplies the metal industry with high quality heat treatment and melting plants for a century.

Our rotary kiln furnace and our metal flow heater are sophisticated technologies that enhance recycling efficiency and enable a transition to clean electricity.